Wood veneers are an essential material in various industries, renowned for their aesthetic appeal and versatility. They provide a cost-effective way to achieve the beauty of real wood while minimizing waste. Wood veneers go through a fascinating manufacturing process, transforming raw logs into thin sheets ready to be used in furniture design, architectural millwork, and interior design. There are different types of wood veneers, including plywood veneer, rotary-cut veneer, half-round cut veneer, quarter-cut veneer, and rift-cut veneer, each offering unique characteristics and patterns.

Wood veneers find applications in a wide range of industries, including furniture design and construction, architectural millwork, and interior design, due to their ability to add warmth, sophistication, and natural beauty to any space. Some advantages of wood veneers include cost-effectiveness, versatile design options, and enhanced stability. They provide a more affordable alternative to solid wood, while offering a wide array of patterns, colors, and textures to choose from.

Veneered surfaces are less prone to warping and shrinking compared to solid wood, making them more stable. When working with wood veneers, certain considerations need to be kept in mind. Proper surface preparation, the selection of adhesives, and maintaining humidity and temperature are crucial factors for successful veneer installation and longevity.

Sustainability and environmental impact are essential considerations in today’s world. Responsible sourcing of wood veneers ensures the preservation of forests, while choosing environmentally-friendly finishing and coating options further minimizes their impact on the environment. Understanding the journey of wood veneers, their types, applications, advantages, considerations, and sustainability aspects provide valuable insights into this remarkable material. From trees to gloss, wood veneers continue to play a significant role in enhancing the beauty and functionality of various industries.

Key takeaways:

- Wood veneers are thin slices of wood that are used to enhance the appearance of various surfaces, such as furniture, architectural millwork, and interior design elements.

- The manufacturing process of wood veneers involves cutting logs into sheets and then slicing those sheets into thin veneers using different techniques like rotary-cut, quarter-cut, and rift-cut.

- Wood veneers offer advantages such as cost-effectiveness, versatile design options, and enhanced stability. However, proper surface preparation, adhesive selection, and maintenance of humidity and temperature are important considerations when working with wood veneers.

The Manufacturing Process: How are Wood Veneers Made?

- The Manufacturing Process: How are Wood Veneers Made?

- Log Selection: Logs of different tree species are carefully chosen based on their color, grain pattern, and quality.

- Peeling: The selected logs are then rotated against a sharp blade, called a veneer lathe, to peel off thin sheets of wood.

- Grading: The veneer sheets are sorted and graded based on their thickness, appearance, and quality.

- Drying: The graded veneer sheets are then dried to remove moisture and stabilize their dimensions.

- Gluing: The dried veneer sheets may be glued together to create thicker or more stable panels.

- Pressing: The glued veneer sheets are pressed under high pressure and heat to ensure proper bonding.

- Sanding: The veneer panels are sanded to achieve a smooth and consistent surface texture.

- Finishing: The sanded veneers may undergo additional treatments like staining, varnishing, or laminating to enhance their appearance and durability.

- Inspection: The finished veneers are meticulously inspected for any defects or flaws and sorted accordingly.

These steps in the manufacturing process contribute to the production of high-quality wood veneers used in various applications such as furniture, cabinetry, and architectural designs.

Types of Wood Veneers

Unlocking the beauty and versatility of wood veneers, this section takes us on a journey through various types of these transformative materials. From the robust and cost-effective plywood veneer to the intricate patterns of the rotary-cut veneer, we will explore the unique characteristics and applications of each. Delving into the artistry of half-round cut veneer, the precision of quarter-cut veneer, and the distinctive linear grain of rift-cut veneer, this section offers a captivating glimpse into the diverse world of wood veneers.

Plywood Veneer

Plywood veneer, also known as wood veneer made from thin layers of plywood sheets, is frequently utilized in furniture design, construction, architectural millwork, and interior design. This specific type of veneer offers numerous benefits such as cost-effectiveness, a wide range of design options, and improved stability. To ensure successful work with plywood veneer, it is crucial to adequately prepare the surface, choose suitable adhesives, and maintain optimal levels of humidity and temperature. When it comes to sustainability and the environment, it is advisable to opt for responsibly sourced plywood veneers and explore various finishing and coating alternatives. Plywood veneer presents itself as a practical and versatile choice for diverse woodworking projects.

Rotary-Cut Veneer

Rotary-cut veneer is a widely used and cost-effective type of wood veneer. It is produced by rotating a log against a blade, resulting in a continuous sheet of veneer. There are several key points to consider when working with rotary-cut veneer:

- Cost-effective: Due to its efficient production process, rotary-cut veneer is often more affordable compared to other types of veneer.

- Natural appearance: The rotary-cutting method enhances the natural grain and texture of the wood, giving it a distinctive and rustic look.

- Wide availability: Rotary-cut veneer can be made from various wood species, offering designers and builders a wide range of options.

- Flexible application: It is commonly used for furniture, cabinets, and architectural millwork because of its ability to be easily bent and shaped for different surfaces.

- Ease of installation: Thanks to its large sheets, rotary-cut veneer can be applied quickly, saving time and effort during the installation process.

When working with rotary-cut veneer, it is crucial to properly prepare the surface, use appropriate adhesives, and maintain the humidity and temperature to prevent warping or deforming. Additionally, consider using sustainably sourced veneers and explore various finishing and coating options to protect and enhance the natural beauty of the wood.

Incorporate these suggestions into your woodworking projects and enjoy the natural beauty and affordability of rotary-cut veneer.

Half-Round Cut Veneer

Half-Round Cut Veneer is a distinct type of wood veneer that showcases a visually appealing grain pattern. Obtained by slicing a log horizontally and rotating it 180 degrees to create a half-circle shape, this veneer offers a unique curved grain pattern that is often used as a decorative element in woodworking. It is commonly employed in high-end furniture, cabinetry, and architectural millwork to enhance the overall design. When using Half-Round Cut Veneer, it is crucial to carefully match patterns and colors to achieve a cohesive and aesthetically pleasing outcome. However, due to its availability constraints, it is advisable to collaborate with suppliers and manufacturers specializing in this particular type of veneer. To introduce a touch of elegance and uniqueness to your next woodworking project, consider incorporating Half-Round Cut Veneer.

Quarter-Cut Veneer

Quarter-cut veneer, also known as “flake” or “fleck,” is a highly sought-after type of wood veneer. It is achieved by cutting the log into quarters and then slicing it perpendicular to the growth rings, resulting in a distinctive grain pattern. The straight grain and consistent appearance of quarter-cut veneer make it a favored choice in furniture making and interior design. Renowned for its stability and resistance to warping, this veneer highlights the natural beauty of the wood grain. As a result, it is frequently utilized to create elegant and sophisticated looks in high-quality furniture pieces.

Rift-Cut Veneer

Rift-cut veneer, also known as comb-grain veneer, is a type of wood veneer that showcases a distinctive linear grain pattern. This unique grain pattern makes rift-cut veneer a popular choice for adding visual interest and sophistication to furniture and architectural millwork. Additionally, rift-cut veneer offers enhanced dimensional stability compared to other types of veneers, making it suitable for applications where stability is crucial.

- Common wood species used for rift-cut veneer include oak, maple, and walnut. These species highlight their natural beauty and characteristics through the linear grain pattern.

- With its clean and linear appearance, rift-cut veneer is often favored for contemporary and modern interior design styles. It brings a touch of sophistication and elegance to spaces.

- Rift-cut veneer is versatile and can be used in various applications such as furniture design, cabinetry, wall paneling, and doors. It offers flexibility in terms of design possibilities and can be stained or finished to achieve different looks.

Applications of Wood Veneers

Wood veneers have found their way into various applications, making their mark in furniture design, construction, architectural millwork, and interior design. In this section, we’ll uncover the fascinating ways wood veneers have transformed these fields. From enhancing the beauty of bespoke furniture to adding warmth and elegance to architectural structures, discover the remarkable versatility that wood veneers bring to these creative domains. Get ready to explore the enchanting fusion of craftsmanship and natural beauty in the realm of wood veneer applications.

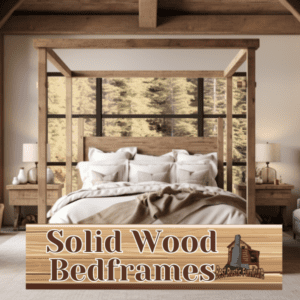

Furniture Design and Construction

When it comes to furniture design and construction, wood veneers provide a wide range of advantages and design options. Here are some key considerations for incorporating wood veneers into furniture:

- Creative Design: Wood veneers enable intricate designs and patterns, enhancing the aesthetic appeal of furniture.

- Durability: Veneered furniture tends to be more resistant to warping and splitting compared to solid wood.

- Cost-effectiveness: Wood veneers offer the appearance of high-end wood species at a lower cost.

- Stability: Veneers help stabilize furniture, reducing the risk of cracking or shrinking caused by changes in humidity.

- Customization: Veneers can be stained or finished to achieve various colors and styles.

Architectural Millwork

Architectural millwork, which involves the use of wood veneers, is widely utilized in various applications within the architectural industry. It offers both functional and aesthetic advantages to different spaces. Below is a comprehensive list of the applications of wood veneers in architectural millwork:

- Doors and Windows: Wood veneers are commonly employed to enhance the appearance of doors and windows, bringing an elegant and warm touch to the space.

- Cabinetry and Shelving: Veneer surfaces are utilized in the construction of cabinets and shelves, providing a durable and visually appealing finish.

- Wall Paneling: The use of wood veneers in creating decorative wall paneling adds texture and visual interest to interior spaces.

- Furniture: Architectural millwork incorporates the use of wood veneers in crafting furniture pieces such as tables, desks, and seating, adding to their allure.

- Ceiling Systems: Wood veneers can be applied to ceiling systems, creating a sophisticated and luxurious ambiance.

Architectural millwork with wood veneers opens up endless design possibilities and brings a touch of natural beauty to any space.

Interior Design

Interior design is one of the key applications of wood veneers. These thin slices of wood are commonly used in interior design to enhance the aesthetic appeal of various interior spaces. Here are some reasons why wood veneers are often opted for in interior design:

- Versatility: Wood veneers offer a wide array of patterns, colors, and textures, making them a versatile choice for creating unique and customized designs in interior spaces.

- Warmth and Natural Beauty: Wood veneers introduce a touch of warmth and natural beauty to interior spaces, producing a cozy and inviting atmosphere.

- Cost-Effectiveness: Wood veneers provide the same look and feel as solid wood but at a lower cost, making them a cost-effective option for interior design projects.

- Easy to Work With: Wood veneers are flexible and can be easily applied to various surfaces, allowing for seamless integration into different design elements.

These qualities make wood veneers an extremely popular choice among interior designers aiming to create visually stunning and environmentally friendly spaces.

Advantages of Wood Veneers

Wood veneers offer a world of advantages that can transform any space. From cost-effectiveness to enhanced stability, each sub-section of this article will dive into the numerous benefits that wood veneers bring to the table. Get ready to discover how wood veneers not only provide versatile design options but also deliver a budget-friendly solution for your next project. Brace yourself for a journey that will make you see wood veneers in a whole new light.

Cost-effective

Wood veneers offer a cost-effective solution for achieving the aesthetic of real wood without the high price tag. There are several reasons why wood veneers are a budget-friendly choice:

- Affordability: Wood veneers are generally cheaper than solid wood, making them a more economical option for projects with budget constraints.

- Reduced wastage: Wood veneers are obtained by slicing or peeling logs, resulting in less wood waste compared to the use of solid wood.

- Optimized use of wood: By utilizing wood veneers, a single log can yield multiple sheets, maximizing the material’s utilization.

- Lower transportation and storage costs: Wood veneers are lightweight and occupy less space, making them more cost-effective to transport and store in comparison to solid wood.

- Extensive variety: Wood veneers come in a wide range of patterns, species, and finishes, granting you the opportunity to achieve your desired look without breaking the bank.

Versatile Design Options

- Wood veneers offer a wide range of design options, allowing for customized patterns and finishes.

- Various Species: Veneers are available in different wood species, which provides a variety of natural colors, grains, and textures for creative design choices.

- Inlays and Marquetry: Wood veneers can be used to create intricate inlays or marquetry designs, adding visual interest and detail to furniture and cabinetry.

- Matching and Sequencing: Veneers can be carefully matched and sequenced to create a continuous and harmonious pattern across large surfaces.

- Curves and Contours: Veneers are flexible and can be applied to curved or irregular surfaces, allowing for unique and organic design elements.

- Combination with Other Materials: Wood veneers can be combined with other materials such as metal or glass to create striking and contemporary design contrasts.

Enhanced Stability

Wood veneers offer enhanced stability, making them a popular choice in various applications. Here is a table highlighting the enhanced stability of wood veneers:

| Application | Enhanced Stability |

|---|---|

| Furniture Design | Wood veneers add strength and durability to furniture pieces. |

| Architectural Millwork | Veneers enhance the stability of doors, panels, and moldings. |

| Interior Design | Veneered surfaces provide stability and longevity to interiors. |

Wood veneers provide a stable and reliable option for these applications, ensuring long-lasting and durable results. The enhanced stability of veneers makes them an ideal choice for projects where strength and durability are essential factors.

Considerations when Working with Wood Veneers

When it comes to working with wood veneers, there are a few key considerations to keep in mind. From ensuring proper surface preparation to selecting the right adhesives and maintaining optimal humidity and temperature, these sub-sections cover all the essential aspects. So, if you’re looking to embark on the journey of working with wood veneers, buckle up and join us on this informative ride!

Proper Surface Preparation

- For the successful application of wood veneers, it is crucial to prioritize proper surface preparation. Follow these steps to ensure proper surface preparation:

- Begin by cleaning the wood surface thoroughly. Use a soft cloth or a vacuum to remove any dirt, dust, or debris.

- Next, take the time to smooth the surface by evenly sanding the wood. This will create a level and smooth base for the veneer application.

- Before moving forward, apply a thin coat of primer to seal the wood surface and improve adhesion.

- To achieve a flawless finish, carefully fill in any cracks, holes, or gaps on the wood surface using wood filler or putty.

- Once the filling is complete, lightly sand the surface again. This final step ensures a seamless and even finish.

Fact: The key to a strong bond between the wood veneer and the substrate lies in proper surface preparation. This diligent approach results in a visually appealing and enduring outcome.

Selection of Adhesives

When working with wood veneers, the selection of adhesives is crucial for a successful and long-lasting application. Consider the following factors when choosing the right adhesive:

- Type of veneer: Different types of adhesives work better with specific veneer types, such as cold press or hot press adhesives.

- Application method: Determine whether you need a liquid adhesive, spray adhesive, or a veneer tape adhesive.

- Bond strength: Consider the level of bond strength required for your project, whether it’s a temporary or permanent bond.

- Compatibility with substrate: Ensure that the adhesive is compatible with the material you are bonding the veneer to, such as wood or MDF.

- Drying time: Consider the drying time of the adhesive, as it can affect your workflow and project timeline.

Using the right adhesive will result in a successful and durable wood veneer application, ensuring that your project stands the test of time.

Maintaining Humidity and Temperature

Incorporating

Proper care and longevity of wood veneers greatly depend on maintaining humidity and temperature levels. To ensure the health of your wood veneer surfaces, follow these steps:

- Monitor humidity levels: It is crucial to keep the humidity between 40-60% to prevent the wood from drying out or absorbing excess moisture.

- Control temperature: Avoid exposing the veneer to extreme temperature fluctuations as they can cause warping or cracking.

- Use a humidifier or dehumidifier: Depending on the season, utilize a humidifier to add moisture or a dehumidifier to reduce humidity levels in the air.

- Protect from direct sunlight: Prolonged exposure to sunlight can lead to color fading and a decline in veneer quality over time.

- Regularly clean and dust: Maintain a clean surface by softly dusting or wiping the veneer with a damp cloth.

Let me share a true story: One of my acquaintances experienced warping in their beautiful wood veneer furniture due to high humidity in their home. They quickly realized the significance of maintaining humidity and temperature levels and decided to invest in a dehumidifier to preserve their furniture. Since then, their wood veneer surfaces have remained in excellent condition.

Sustainability and Environmental Impact

Wood veneers have come a long way, and in this section, we’ll dive into their sustainability and environmental impact. Discover the world of responsibly sourced wood veneers, and how they contribute to a greener future. We’ll also explore the different finishing and coating options available, ensuring that beauty and sustainability go hand in hand. So get ready to delve into the fascinating journey of wood veneers, where eco-consciousness meets exquisite craftsmanship.

Responsibly Sourced Wood Veneers

Responsible sourcing of wood veneers is vital for sustainable and environmentally friendly practices. To ensure the selection of wood veneers from responsible sources, it is important to consider the following guidelines:

– Look for certifications such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC).

– Confirm that the veneers originate from well-managed forests with documented chain-of-custody.

– Avoid purchasing veneers sourced from endangered tree species or illegal logging operations.

By actively choosing responsibly sourced wood veneers, you actively contribute to forest preservation and promote ethical practices within the woodworking industry. Remember, making informed choices can positively impact both the environment and society.

Finishing and Coating Options

When it comes to wood veneers, choosing the right finishing and coating options is essential to achieve the desired look and protect the wood surface.

- To enhance the natural beauty of the wood and add depth to the color, you can apply a stain as part of the finishing and coating options.

- For sealing the wood surface and protecting it from moisture, stains, and UV damage, it is recommended to use a sealer.

- When aiming for a durable and glossy finish that highlights the wood’s grain, lacquer can be applied as one of the finishing and coating options.

- Creating a protective coating that is resistant to scratches and heat can be achieved by using varnish among the available finishing and coating options.

- Applying oil is a great option to enhance the wood’s natural beauty, provide a satin finish, and protect against moisture as part of the finishing and coating options.

Some Facts About “From Trees to Gloss: The Journey of Wood Veneers”:

- ✅ Wood veneer is a versatile material used in woodworking to create stunning effects in furniture and other wood products. (Source: woodshopdirect.co.uk)

- ✅ There are different types of wood veneer, including raw wood veneer, paper-backed veneer, phenolic-backed veneer, and laid-up veneer. (Source: woodshopdirect.co.uk)

- ✅ Wood veneer is used in various applications, including furniture, cabinetry, musical instruments, and marquetry. (Source: woodshopdirect.co.uk)

- ✅ Wood veneer allows manufacturers to create beautiful, high-quality pieces at a fraction of the cost of solid wood. (Source: woodshopdirect.co.uk)

- ✅ Wood veneer plays a significant role in sustainable practices, as it allows for more surface area to be covered with less wood, reducing the need for harvesting trees. (Source: woodshopdirect.co.uk)

Frequently Asked Questions

How does YouTube work?

YouTube is a platform owned by Google LLC that allows users to upload, share, and watch videos. It offers a wide range of features and functions, including the ability to search for videos, create playlists, subscribe to channels, and interact with other users through comments and likes. Additionally, YouTube provides opportunities for content creators to monetize their videos through advertising and partnerships.

Can I test new features on YouTube?

Yes, YouTube often introduces new features and updates to improve user experience. As a user, you may have the option to test these new features by participating in YouTube’s beta testing program. This allows you to provide feedback and try out upcoming features before they are rolled out to the general public.

What is phenolic-backed veneer?

Phenolic-backed veneer is a type of wood veneer that offers extra strength and durability. It has a layer of phenolic resin applied to the back of the veneer, which provides added stability and moisture resistance. This type of veneer is commonly used in applications where durability is essential, such as high-traffic areas or environments with high humidity.

How can I terminate my contracts on YouTube?

If you wish to terminate your contracts on YouTube, you can do so by reviewing and adhering to the terms of use, privacy policy, and guidelines for safety provided by the platform. These documents outline the procedures and requirements for contract termination. You can find links to these documents on YouTube’s website.

What is the significance of the copyright notice for 2023 Google LLC?

The copyright notice for 2023 indicates that the content or information provided on YouTube, which is owned by Google LLC, is protected by copyright laws. It serves as a reminder that unauthorized use or reproduction of the content without proper permission may result in legal consequences. This notice helps to ensure that the intellectual property rights of content creators and YouTube itself are respected and upheld.

What is laid-up veneer and its application in high-end furniture?

Laid-up veneer is a type of wood veneer that is used in the production of high-end furniture and cabinetry. It involves layering multiple sheets of thin wood veneer onto a substrate to create a thicker, more substantial look. This technique allows manufacturers to achieve a luxurious and visually impressive finish. Laid-up veneer is often preferred for premium furniture pieces where aesthetics and quality are paramount.