Creating log furniture allows you to bring the natural beauty and rustic charm of logs into your home. Not only does it offer a unique and personalized touch to your space, but it also provides several benefits. In this article, we will explore the benefits of making log furniture, the process of choosing the right logs, the necessary tools and equipment, as well as the techniques for preparing and joining the logs. We will also delve into finishing techniques, advanced designs, and provide tips for maintenance and care. So, whether you are a seasoned woodworker or a beginner looking to embark on a new DIY project, this article will guide you through the process of making log furniture and help you create stunning pieces that will last for years to come.

Key takeaways:

- Making log furniture requires choosing the right logs: Consider the tree species, log size, shape, condition, and moisture content to ensure a successful project.

- Proper preparation of the logs is essential: Debark the logs, remove knots and rough bark, and dry them thoroughly before starting the construction process.

- Mastering joinery and assembly techniques is crucial: Learn basic techniques like mortise and tenon, dovetail, and half-lap joints to create sturdy and durable log furniture.

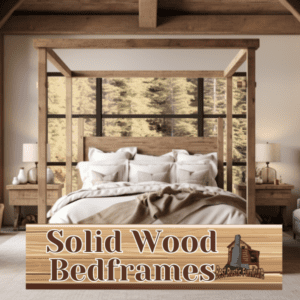

Benefits of Making Rustic Log Furniture

- Making log furniture offers several benefits for both the environment and individuals.

- Sustainable: Using logs from sustainable sources reduces the impact on forests and promotes responsible forestry practices.

- Cost-effective: Log furniture can be more affordable than traditional furniture, especially if you have access to logs or can source them locally.

- Durable: Log furniture is known for its durability and sturdiness, as it is made from solid wood logs that can withstand wear and tear.

- Unique and Customizable: Each piece of log furniture is unique, showcasing the natural characteristics of the wood. It can also be customized to fit your specific needs and preferences.

- Rustic Charm: Log furniture adds a rustic and cozy charm to any space, bringing the beauty of nature indoors.

Choosing the Right Logs

Choosing the right logs is crucial when it comes to making log furniture. In this section, we will explore the different factors to consider, such as the tree species, log size and shape, and log condition and moisture content. Get ready to discover how these elements play a vital role in creating stunning and durable log furniture pieces. So, let’s dive into the world of log selection and learn the secrets to crafting beautiful and long-lasting furniture from natural, rustic materials.

1. Tree Species

The selection of tree species is vital when creating log furniture because different types of wood possess unique characteristics and qualities. Refer to the following table for details on popular tree species utilized in log furniture:

| Tree Species | Wood Characteristics |

|---|---|

| Oak | Strong, durable, and resistant to decay |

| Pine | Lightweight and easy to work with |

| Cedar | Naturally resistant to rot and insects |

| Walnut | Beautiful grain pattern, ideal for intricate designs |

| Maple | Hard and sturdy, perfect for structural elements |

| Birch | Smooth texture and attractive appearance |

Understanding the qualities of each tree species will aid in selecting the appropriate wood for your log furniture project, ensuring both durability and aesthetic appeal.

2. Log Size and Shape

The size and shape of logs are of utmost importance when creating log furniture. Log Size and Shape greatly influence the uniqueness and distinctiveness of furniture pieces. When selecting logs, it is essential to consider the following factors related to Log Size and Shape:

1. Diameter: By taking into account the logs’ diameter, you can determine the desired thickness for your furniture pieces. Tables benefit from using thicker logs, whereas chairs and smaller items thrive with thinner logs. 2. Length: Logs should be chosen based on their length to ensure they can fit the desired dimensions of your furniture. Longer logs are necessary for constructing items such as benches or bed frames. 3. Straightness: Logs with minimal bends or twists are preferable. Straight logs are easier to work with and yield a more professional-looking finished piece. 4. Uniformity: It’s advisable to select logs that are similar in size and shape to achieve a cohesive appearance. A consistent look enhances the overall aesthetic of your log furniture.

Always keep in mind that Log Size and Shape significantly impact the final design and functionality of your log furniture.

3. Log Condition and Moisture Content

To ensure the quality and durability of log furniture, it is crucial to consider the condition and moisture content of the logs used. Log Condition and Moisture Content can be determined by assessing the following factors:

1. Log Check: Inspect the logs for cracks or checks, as these can compromise the structural integrity of the furniture.

2. Beetle Damage: Look for signs of beetle infestation, such as small holes or exit marks. Infested logs should be avoided, as they may weaken the furniture.

3. Moisture Content: Measure the moisture content of the logs using a moisture meter. Logs with a moisture content of 15% or lower are ideal for furniture making, as excessive moisture can lead to warping and shrinking.

To maintain accuracy, it is important to gather information from reliable sources, such as experienced craftsmen or woodworking experts, who have extensive knowledge and expertise in log furniture making. Understanding the Log Condition and Moisture Content of logs will greatly contribute to creating durable and long-lasting log furniture pieces.

Historical

Tools and Equipment Needed for Making Log Furniture

When making log furniture, having the right tools and equipment is essential for a successful project. Here is a list of the necessary tools and equipment needed:

- Chainsaw: This powerful tool is used to cut the logs into the desired shapes and sizes.

- Woodworking tools: These include chisels, hammers, and saws for shaping and smoothing the wood.

- Drill: A drill is necessary for making holes and attaching various components of the furniture together.

- Sandpaper and finishing materials: These are needed to give the furniture a smooth and polished look.

- Clamps: Clamps are used to hold the logs in place while working on them.

- Safety equipment: Protective gear such as goggles, gloves, and ear protection should be worn while using the tools.

Log furniture has been around for centuries, with evidence dating back to ancient Egypt and Rome. It was a popular choice in frontier America, where settlers crafted furniture from logs. Today, log furniture is cherished for its rustic beauty and natural appeal, making it a timeless choice for decorating cabins, lodges, and nature-inspired homes.

Preparing the Logs

Preparing the Logs is a crucial step in the process of making log furniture, where we carefully transform raw logs into beautiful and functional pieces. In this section, we will explore the necessary techniques to make the logs suitable for furniture construction. From debarking and removing knots to ensuring proper drying, each sub-section will reveal the essential details for achieving high-quality results in log furniture craftsmanship. So, grab your tools and let’s dive into the art of preparing logs!

1. Debarking the Logs

Debarking the logs is a crucial step that plays a vital role in the process of making log furniture. Not only does it aid in the preparation of the logs for subsequent processing, but it also acts as a preventative measure against moisture buildup, insect infestation, and decay. To guide you through the process of debarking the logs, here are the steps you should follow:

| 1. | To begin, securely fasten the log in place using clamps or a log bench. |

| 2. | Next, use a draw knife or a bark spud to delicately and meticulously eliminate the bark with fluid, elongated strokes. |

| 3. | While working your way around the log, pay close attention to any knots or rough patches. |

| 4. | To ensure thorough removal of any remaining bark or loose fibers, utilize a wire brush or coarse sandpaper to gently scrape them away. |

| 5. | Thoroughly inspect the log, searching for any lingering rough spots or areas that require further debarking. |

| 6. | Once the log is completely free of bark, cleanse its surface by carefully wiping it down with a damp cloth. |

Properly debarking the logs will result in a smoother surface, enabling further preparation and significantly enhancing the overall aesthetics and durability of your log furniture.

2. Removing Knots and Rough Bark

- To remove knots and rough bark when making log furniture, follow these steps:

- Use a chainsaw or hatchet to carefully cut around the knot, removing knots and rough bark from the log.

- With a drawknife or chisel, remove any knots and rough bark around the knot area.

- Use sandpaper or a power sander to smooth the surface of the log, ensuring it is free from any remaining rough spots or bark.

Remember to wear safety gear and take caution when removing knots and rough bark. By following these steps, you will achieve a smooth and clean surface for your log furniture.

3. Drying the Logs

- Drying the logs is a crucial step in the process of making log furniture in order to prevent cracking and warping.

- To ensure proper airflow, store the logs in a dry, well-ventilated area.

- To prevent moisture from seeping back into the logs, elevate them off the ground using pallets or supports.

- It is important to monitor the moisture content of the logs using a moisture meter. Aim for a moisture content of approximately 20%.

- In order to achieve even drying and prevent uneven shrinkage, make sure to rotate the logs regularly.

- You may consider implementing kiln drying or air drying methods to expedite the drying process.

- Before using the logs for furniture construction, allow them to dry for a minimum of six months to a year.

- Periodically check the moisture content of the logs to ensure they are adequately dried before commencing the furniture-making process.

Basic Techniques for Joinery and Assembly

In the world of crafting log furniture, mastering the art of joinery and assembly is crucial. Get ready to dive into the realm of basic techniques that will elevate your woodworking skills. From the time-tested mortise and tenon joints to the intricate dovetail joints, and the versatile half-lap joints, we’ll explore these methods that form the backbone of log furniture construction. So grab your tools and let’s unlock the secrets to crafting beautiful and sturdy log furniture pieces.

1. Mortise and Tenon Joints

- Mortise and Tenon Joints: These strong and durable joints, commonly used in log furniture construction, involve a protruding tenon on one piece of wood that fits into a mortise on the other piece.

- Accuracy is crucial: Precise measurements and cuts are essential to ensure a tight and secure fit when working with mortise and tenon joints.

- Choose the right tools: When creating the mortise, a mortising machine or a chisel and drill are commonly used, while a tenoning jig or hand saw can shape the tenon.

- Proper assembly: To add strength and durability, apply glue to the joint surfaces and use clamps to secure the pieces while the glue dries.

- Variations: There are different types of mortise and tenon joints, including through-tenons, blind tenons, and wedged tenons, each with unique characteristics and uses.

By mastering the art of creating mortise and tenon joints, you can confidently build beautiful and sturdy log furniture pieces that will stand the test of time.

2. Dovetail Joints

- Dovetail joints, also known as the finest joints in woodworking, are essential in creating sturdy and durable log furniture pieces.

- Here are the steps to create impeccable dovetail joints:

- Start by measuring and marking the logs to determine the precise placement of the dovetail joints.

- Use a saw to carefully cut out the tails, following the marked lines, on one log.

- Next, measure and transfer these tail markings to the mating log, ensuring accuracy in alignment.

- Carefully cut out the pins on the mating log, making sure they align perfectly with the tails.

- Once completed, fit the perfectly-crafted tails and pins together, creating a tight and secure connection.

- To ensure maximum strength, it is recommended to secure the joints with high-quality wood glue and clamps.

- Allow the glue to dry completely before proceeding with any further assembly.

To achieve precise and professional-looking dovetail joints, extensive practice and unwavering patience are key. It is also beneficial to experiment with different log sizes and shapes, as this will enable you to create unique and eye-catching designs. Good luck with your log furniture-making journey!

3. Half-lap Joints

- Half-lap joints are commonly used in log furniture construction due to their strength and stability. Here is a step-by-step guide on how to create half-lap joints:

- Measure and mark the halfway point on both logs that will be joined.

- Using a saw, make straight cuts along the marked lines until half the depth of the logs.

- Remove the wood between the cuts using a chisel or a router to create a notch.

- Repeat the process on the second log, ensuring that the notches align.

- Fit the notches together, ensuring a snug and flush fit.

- Secure the joint by applying wood glue and using clamps to hold the logs together until the glue dries.

- For added strength, you can also drill and install dowels or screws through the joint.

Half-lap joints have been used in woodworking for centuries and were favored for their simplicity and strength. This type of joint was commonly used in traditional timber framing and has stood the test of time due to its reliability and durability. Today, it is still widely used in log furniture construction for its ability to create sturdy and visually appealing connections between logs.

Finishing Techniques for Log Furniture

Enhance the beauty and durability of your log furniture with these expert finishing techniques. Discover the art of sanding and smoothing the surface, achieving a flawless texture that will leave your furniture looking stunning. We will also explore the application of a protective finish, ensuring long-lasting protection against wear and tear. Get ready to learn the secrets behind creating log furniture that not only captures attention but stands the test of time.

1. Sanding and Smoothing the Surface

To achieve a smooth and polished surface for log furniture, the process of sanding and smoothing the surface is essential. Here are the steps to sanding and smoothing the surface:

- Begin with coarse-grit sandpaper to remove any rough edges or imperfections.

- Gradually move to finer-grit sandpaper to smooth out the surface, working in the direction of the grain.

- Focus on areas that require more attention, such as knots or blemishes, by sanding them with extra care.

- Wipe away dust and debris with a damp cloth or tack cloth to ensure a clean surface.

- For a smoother finish, use a sanding block or sanding sponge to evenly distribute pressure.

- Inspect the surface for any remaining imperfections and repeat the sanding process as needed.

- Once satisfied with the smoothness, finish the surface with a protective coating or stain to enhance the appearance and durability of the log furniture.

Throughout history, log furniture has been crafted using techniques like sanding and smoothing the surface to create both functional and beautiful pieces that reflect the natural beauty of wood.

2. Applying a Protective Finish

- To protect log furniture from wear and tear and enhance its natural beauty, one should follow the crucial step of applying a protective finish.

- Start by preparing the surface of the furniture, sanding it down to remove any rough patches or imperfections.

- Make sure to clean the surface thoroughly, ensuring it is free from dust and debris.

- If desired, apply a wood stain by following the manufacturer’s instructions.

- Allow the stain to dry completely before proceeding to the next step.

- Using a brush or a roller, apply a protective finish such as polyurethane or varnish.

- Be sure to apply an even layer, covering the entire surface of the furniture.

- Allow the protective finish to dry according to the manufacturer’s instructions.

- If desired, repeat the process by applying multiple coats for added durability.

By following these steps, not only will your log furniture be visually appealing, but it will also endure for a long time.

Advanced Techniques and Designs

Discover the next level of artistry and craftsmanship in log furniture making. In this section, we will dive into the realm of advanced techniques and designs, pushing the boundaries of what you thought was possible with logs. From the intricate art of carving and sculpting to the enchanting addition of inlays and decorative elements, get ready to explore the limitless possibilities that lie ahead. Let your imagination run wild as we unveil the secrets to creating awe-inspiring log furniture like never before.

1. Carving and Sculpting

Carving and sculpting are vital techniques when creating log furniture. These methods allow for the development of intricate designs and personalized details on the logs. Here is a step-by-step guide for incorporating carving and sculpting into your log furniture:

- Select a Design: Begin by deciding on the design or pattern you wish to carve onto the log.

- Prepare the Log: Before starting the carving process, ensure that the log is properly dried and smoothed.

- Mark the Design: Use a pencil or chalk to mark the design onto the log, serving as a helpful guide during the carving process.

- Carve the Log: Utilize carving tools like chisels, gouges, and saws to carefully remove the wood and shape it according to your desired form and texture.

- Refine and Finish: Smooth out any rough edges or areas and refine the carving’s details using sandpaper or small tools.

- Protect and Preserve: Enhance the durability and longevity of the carved surface by applying a protective finish, such as varnish or wood sealant.

2. Adding Inlays and Decorative Elements

To add inlays and decorative elements to your log furniture, follow these steps:

- Choose the type of inlay or decorative element you want to incorporate, such as wood, metal, or resin.

- Select the specific design or pattern you want to create and mark the areas of the log where the inlay or element will be placed.

- Use appropriate tools like chisels, drills, or routers to create the recess or groove for the inlay or element.

- Prepare the inlay or decorative element by shaping or cutting it to fit the recess or groove.

- Apply adhesive or epoxy resin to secure the inlay or element in place.

- Allow sufficient time for the adhesive or resin to dry and cure.

- Sand the surface to remove any excess adhesive and smooth out any rough spots.

- Apply a protective finish to the entire piece of log furniture to enhance its durability and appearance.

A skilled craftsman once created a stunning log coffee table by adding intricate wood inlays depicting local wildlife. The process of adding inlays and decorative elements to the log furniture was carefully followed. The intricate details and natural beauty of the inlays brought the table to life, making it a conversation piece in the room. The skill and creativity showcased in the log furniture’s design, along with the incorporation of inlays and decorative elements, left a lasting impression on anyone who saw it.

Tips for Maintenance and Care

Properly caring for your log furniture is essential to ensure its long lifespan and preserve its beauty. Follow these tips for maintenance and care:- Clean regularly: Dust and debris tend to accumulate on log furniture surfaces. To keep it clean, use a soft brush or cloth to gently remove dirt.

- Protect from moisture: Log furniture is prone to damage from moisture. To prevent water infiltration and warping, make sure to apply a protective sealant.

- Maintain humidity levels: Wood can expand or shrink due to changes in humidity. To avoid cracks or splits, it’s important to maintain a stable indoor humidity level.

- Avoid direct sunlight: The prolonged exposure of log furniture to sunlight can lead to fading and wood damage. Position your furniture away from direct sunlight or use curtains or blinds to provide protection.

- Repair as needed: Regularly inspect your log furniture for any signs of wear or damage. Promptly repair any loose joints or cracks to prevent further deterioration.

Some Facts About How To Make Log Furniture:

- ✅ Basic tools are all that’s needed to make log furniture. (Source: logfurniturehowto.com)

- ✅ You can start making log furniture with what you have and gradually acquire new tools. (Source: logfurniturehowto.com)

- ✅ Making log furniture requires using the available materials and tools based on your knowledge and skills. (Source: logfurniturehowto.com)

- ✅ As you progress in making log furniture, you will discover new tools and techniques that fulfill your needs. (Source: logfurniturehowto.com)

- ✅ Being open to new ways of doing things and prepared for unexpected needs is essential in making log furniture. (Source: logfurniturehowto.com)

Frequently Asked Questions

1. How do I make log furniture using basic tools?

Making log furniture is possible with basic tools that can be easily acquired over time and as needed. Start by using what you have and make a plan based on your knowledge. As you progress, be open to learning and acquiring new tools to fulfill your needs.

2. What are the advantages of making log furniture?

Making log furniture allows you to create unique and rustic pieces that have a distinctive mark of craftsmanship. It provides the satisfaction and value of creating something with your own hands and passing it on to the next generation. Moreover, it can be a cost-effective alternative to buying machined furniture.

3. How do I find the best logs for furniture building?

When sourcing logs for furniture building, it is important to avoid trees with potential hazards like buried nails. Look for standing dead trees, fallen limbs, or yard trees that have been cut down. Consider using specialized tools like a metal detector to identify hidden nails and a moisture meter to assess the wood’s moisture content.

4. Should I leave the bark on or remove it from the wood?

The decision to leave the bark on or remove it from the wood depends on personal preference and the wood species being used. Some prefer the rustic look of leaving the bark on, while others remove it for a cleaner and more polished appearance. Consider the pros and cons of each option and choose what fits your desired aesthetic.

5. What are the common techniques for joining wood in log furniture?

There are various techniques for joining wood in log furniture, including tenons, dowel pins, nails, nail guns, lag bolts, screws, and biscuit joiners. Each method has its own advantages and considerations. It is important to understand the strengths and limitations of each technique and choose the one that suits your specific project.

6. How do I finish log furniture?

Finishing log furniture involves applying protective coatings to enhance its appearance and durability. Consider setting up a separate finishing booth with good lighting and air filtration for better results. The choice of finishing method depends on personal preference, but it is recommended to explore different options like oils, varnishes, or paints to achieve the desired outcome.